Predictive maintenance technology is revolutionizing industries by enabling proactive and data-driven maintenance strategies. By harnessing the power of data analytics, machine learning, and sensor technology, predictive maintenance helps organizations optimize their maintenance practices, reduce downtime, and enhance operational efficiency. This transformative approach ensures that equipment and machinery are serviced exactly when needed, maximizing their lifespan and minimizing disruptions.

1. Understanding Predictive Maintenance:

Predictive maintenance is a proactive maintenance strategy that leverages real-time data and advanced analytics to predict when equipment is likely to fail. Unlike traditional maintenance approaches that rely on fixed schedules or reactive interventions, predictive maintenance allows organizations to address issues before they escalate into costly breakdowns.

2. The Benefits of Predictive Maintenance:

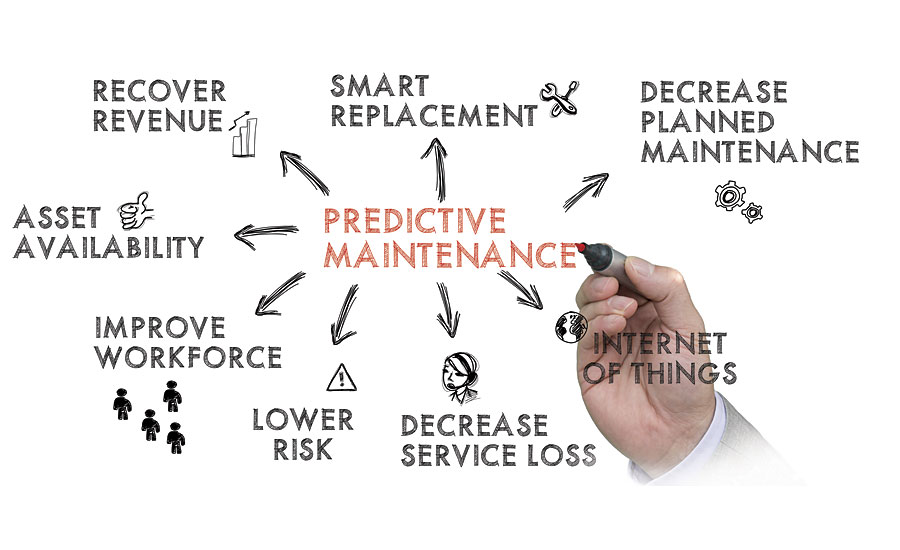

Predictive maintenance technology offers a wide range of benefits that impact various aspects of operations:

- Reduced Downtime: By identifying potential failures in advance, organizations can schedule maintenance during planned downtime, minimizing unexpected disruptions.

- Cost Savings: Proactive maintenance reduces emergency repairs and extends the lifespan of equipment, resulting in significant cost savings.

- Optimized Resource Allocation: Resources such as labor, spare parts, and maintenance teams can be allocated more efficiently based on data-driven insights.

- Improved Safety: Regularly monitored equipment reduces the likelihood of accidents caused by faulty machinery.

- Enhanced Operational Efficiency: Predictive maintenance helps streamline operations by reducing unnecessary maintenance activities and maximizing equipment availability.

- Data-Driven Decision-Making: Insights gained from predictive maintenance data can inform strategic decisions about equipment replacement, upgrades, and investments.

3. Methods of Predictive Maintenance:

Predictive maintenance employs a combination of methods and technologies to predict equipment failures:

- Condition Monitoring: Sensors and IoT devices continuously monitor equipment conditions, capturing data on parameters like temperature, vibration, and pressure.

- Data Analytics: Advanced analytics and machine learning algorithms process large volumes of data to detect patterns, anomalies, and potential failure indicators.

- Predictive Modeling: Historical data is used to build predictive models that forecast equipment performance and identify trends over time.

- Fleet-wide Analysis: Organizations can analyze data from a fleet of similar equipment to identify common failure patterns and optimize maintenance strategies.

4. Challenges and Considerations:

While predictive maintenance technology offers immense advantages, there are challenges to overcome:

- Data Quality and Integration: Reliable predictive insights depend on accurate and comprehensive data from various sources.

- Skill Gaps: Implementing and managing predictive maintenance requires skilled personnel with expertise in data analytics and technology.

- Change Management: Transitioning from traditional maintenance practices to predictive approaches may require cultural and operational adjustments.

- Initial Investment: Adopting predictive maintenance technology involves costs related to sensor deployment, data infrastructure, and training.

5. Applications Across Industries:

Predictive maintenance technology has widespread applications across various sectors:

- Manufacturing: Factories use predictive maintenance to optimize production lines, reduce downtime, and enhance product quality.

- Energy and Utilities: Power plants and utilities leverage predictive maintenance to optimize maintenance schedules for turbines, generators, and distribution systems.

- Transportation: Airlines, railways, and logistics companies use predictive maintenance to ensure the reliability of vehicles and infrastructure.

- Oil and Gas: Predictive maintenance helps prevent costly downtime in oil refineries and offshore drilling operations.

- Healthcare: Hospitals use predictive maintenance to ensure the uptime of critical medical equipment and devices.

6. Future Trends and Innovations:

The evolution of predictive maintenance technology holds exciting possibilities:

- IoT Integration: The Internet of Things will enable even more data-rich insights by connecting an increasing number of devices and equipment.

- Edge Computing: Processing data closer to the source (edge) will reduce latency and enhance real-time decision-making.

- Predictive Analytics Advancements: Improved algorithms and machine learning techniques will lead to more accurate and precise predictions.

- AI-Driven Insights: Artificial intelligence will play a pivotal role in analyzing complex data sets and driving predictive insights.

- Digital Twins: Virtual representations of physical assets will facilitate real-time monitoring and predictive modeling.

7. Conclusion: The Future of Maintenance Management

Predictive maintenance technology represents a paradigm shift in maintenance management, allowing organizations to transcend reactive approaches and embrace proactive strategies. By harnessing the power of data and technology, businesses can optimize their operations, reduce costs, and enhance reliability. As predictive maintenance continues to evolve and integrate with emerging technologies, it holds the promise of transforming industries, enabling a future where downtime is minimized, resources are optimized, and operational excellence is achieved.